The Delta Drill Press Project

1955 Delta DP 17-600

The Delta Project has been one of the most rewarding restoration efforts for me in a long time. I had been wanting to upgrade my drill press for quite a while. When starting my research for what I needed, I quickly realized that a new machine of the caliber I wanted was going to be out of my budget. Then, I discovered the world of vintage machinery, and the people devoted to saving them. These enthusiasts are restoring, trading and swapping parts out machines from the heyday of American Manufacturing. All kinds of machines that were built so well that they are still usable or rebuildable after 85 years. Many were used during World War II to build the greatest force for democracy the world had ever seen. These epic machines hold so much history and significance that I wish they could talk. Then, I knew, that one of these magnificent machines was what I was looking for. Now, which one…

Making the Choice… As I happily went down this rabbit hole I had many things to consider. I needed a machine that had larger capacity and stability than my current drill press, but it still had to be practical. I didn’t need a one ton milling machine (actually, I do but my current shop isn’t big enough), instead I needed a full size industrial drill press. My father, who owned several wood related businesses, always bought Delta machines because he trusted their quality. So that was a start, a kind of an emotional, in “honor of him” thing. Also, Delta offered several sizes of machines from “home owner benchtop” models, to full sized, standing industrial floor models. I have even seen multiple headed units for machine shop production with 2, 3 or 4 heads and oil bath tables. Finally, Delta had large production numbers for many years, going way back to the late 1930’s, so finding a machine and spare parts would be easier.

The answer ended up being their DP 17-600 model, a 400lb cast iron behemoth with a 17 inch swing and 5 inch stroke. It is arguably the finest drill press ever made. Now to find one…

The Quest…When researching, I discovered a forum called Old Woodworking Machines (https://owwm.org/index.php). These guys live and breathe this stuff, I ended up joining the group in order to see their classifieds and to stay abreast of any thoughts and technical info. They scour the country looking at auction houses and shops who offer these machines to sell. Many times machine shops and wood shops finally let these vintage machines go when they want to upgrade or when they go out of business. So, these amazing machines are available but you have to search. One of the guys on the forum rebuilds various machines in his spare time and actually sells them at good prices. He does a really good job and his stuff sells quick. I was ready to drive to Michigan (from Florida!) to get his latest, which happened to be a 17-600, but it was already gone. When I spoke to him he gave me a few names of people who may have some early Deltas available but not necessarily in refurbished condition.

This is how I came to know a man named Alan in Virginia (for his contact info, please email me). Alan’s life passion has been about these old machines. He still works part time as a machinist but spends most of his time finding and gathering these amazing pieces of history. I bought one of the three 17-600’s he had stashed around one of his properties. My son and I drove to Virginia to get it, and brought it home to begin the effort.

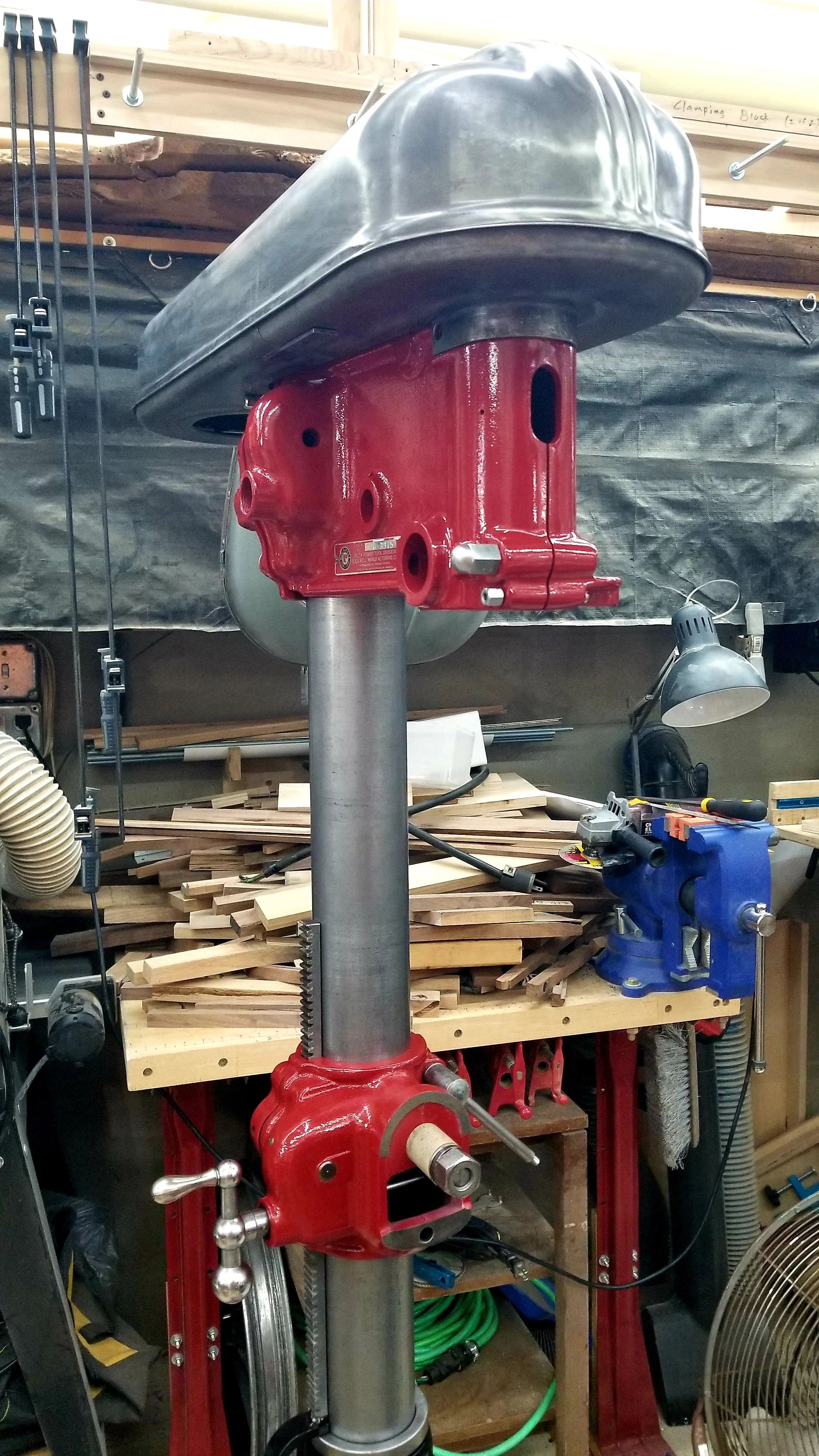

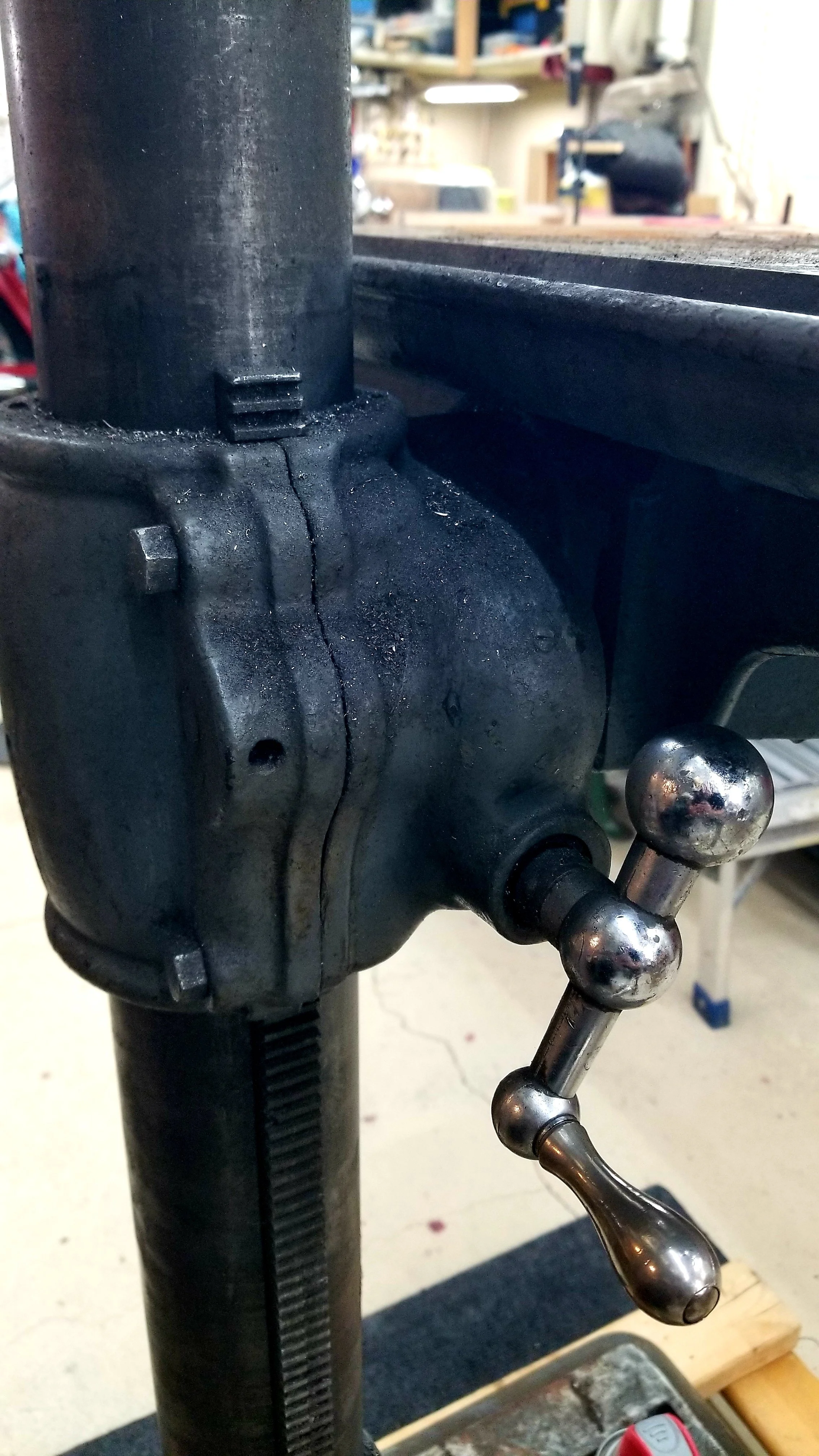

Disassembly… Delta DP 17-600 #116-3975 was built by Rockwell Manufacturing in Pittsburgh PA in 1955. Alan bought it at an auction along with another 17-600 from a machine shop. They told him it had been working until recently and they had owned it forever. This machine had seen continuous work for close to 70 years and obviously been maintained but was tired and dirty. It was layered with crud, a semi-hard mixture of grease and metal shavings. The forum guys call it sludge. After scraping off as much as possible, I started removing major components and bagging and labeling the smaller parts. The goal was to get down to the individual castings for major cleaning and a repaint. Degreasing, stripping and grinding off the old paint took almost a week and a mask must be worn because this old paint usually contains lead. If I were doing it again, I would definitely set up a sand blasting operation. The castings are amazingly stout but occasionally there can be cracks in machines this old, fortunately mine was undamaged.

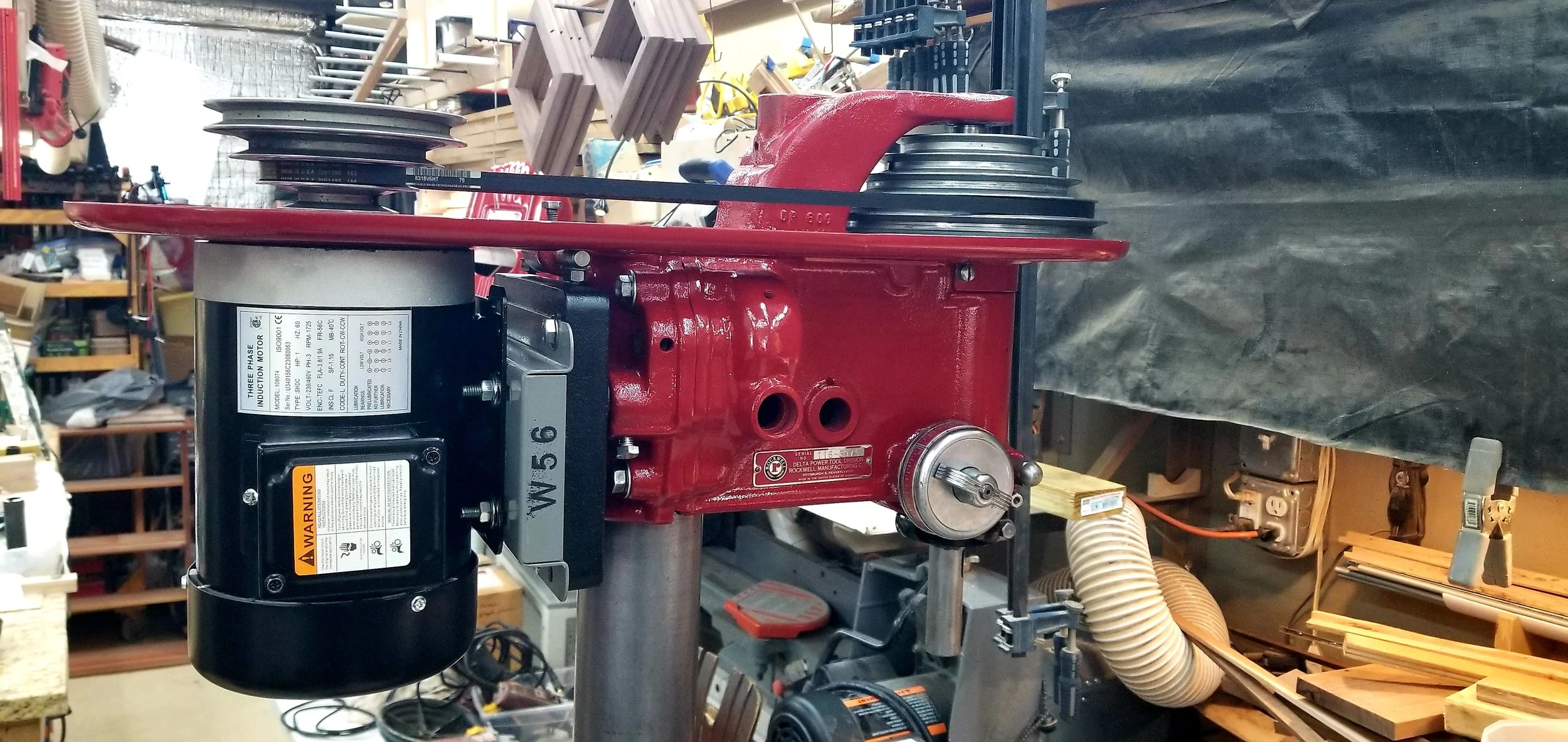

Massive internal components were astounding, large hardened gears and splined shafts were covered in dried grease but in perfect condition once cleaned, amazing after so many years of hard use. The large quill still had smooth movement and just needed cleaning, lube and a small adjustment. I did end up replacing more parts than initially expected. Both belt pulleys needed to go, they were loose on their shafts after too many times of bits getting locked up on work pieces and damaging them. Plus I wanted to replace the motor pulley for a “Slow speed” unit, more appropriate speeds for woodworking than machining steel. The only bearing that needed replacement was the one on top of the front pulley. In the pictures you can see the massive support casting that goes up over the this pulley, it has a bearing to hold the top of the upper quill spline shaft. The other internal spline shaft bearings were all tight and smooth, probably replaced in the past 20 years or so. I did replace several smaller parts due to normal wear, and put in a new return spring for the quill.

Upgrades… This was my favorite part. Let’s take a vintage machine, large and overbuilt, and give it a modern heart transplant. I had seen variable speed machines before, some of the newest drill presses feature direct drive (instead of belt driven) and variable speed motors. Plus, the guys and gals on the forum were updating many of their machines to VFD for more convenience and adjustability. I had planned to do this a some point in the future but when I took apart the original motor on this Delta to rebuild it with new bearings and brushes, the internal wiring just disintegrated. I knew it was time to do it right the first time.

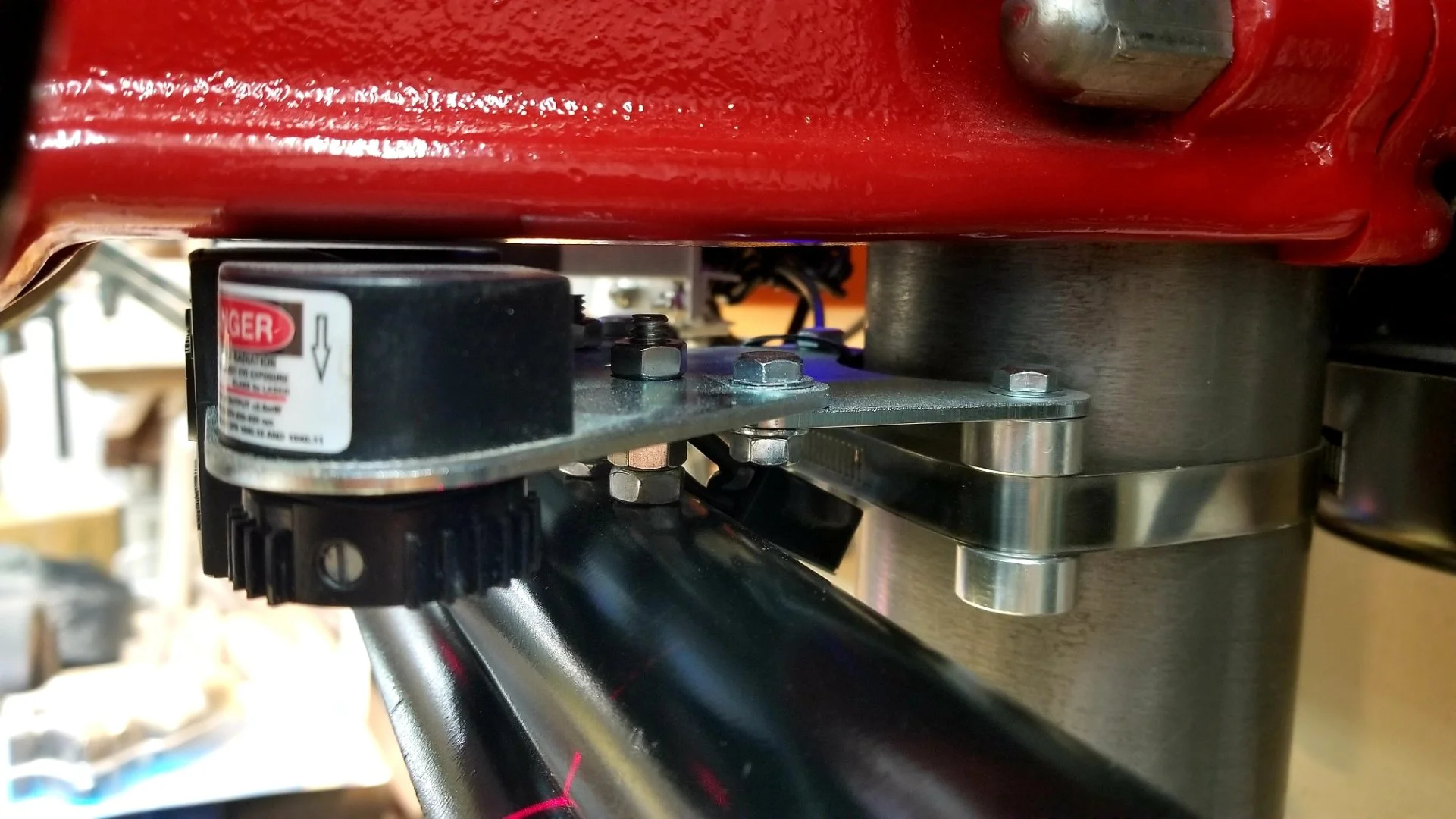

VFD Variable Frequency Drive… I used input from the forum to find a good option for the controller to do this upgrade and was directed to Automation Direct (https://www.automationdirect.com/adc/home/home) . I ordered their “DURApulse GS10 series AC micro drive” to control a new 1hp 240v 3 phase motor that I got on sale from Amazon. The hardest part of this upgrade was getting the motor mounted in the correct location. They sell a variety of motor mounts to adapt motors to base plates that allow adjustability, but none would fit the old Delta. I ended up drilling new holes in the old baseplate to align with the new adapter and modifying it so it so the old base would get close enough to the head casting to allow the belt to go on and off. Next I had to fabricate a mount for the controller on the left side of the head unit. I used a large hole that extends left to right through the casting that would normally support a power unit that drives the quill up and down in industrial applications. Spacers and large bolt connect to a plate on the left that holds the VFD, tachometer and 120v power strip for the lights and laser guide.

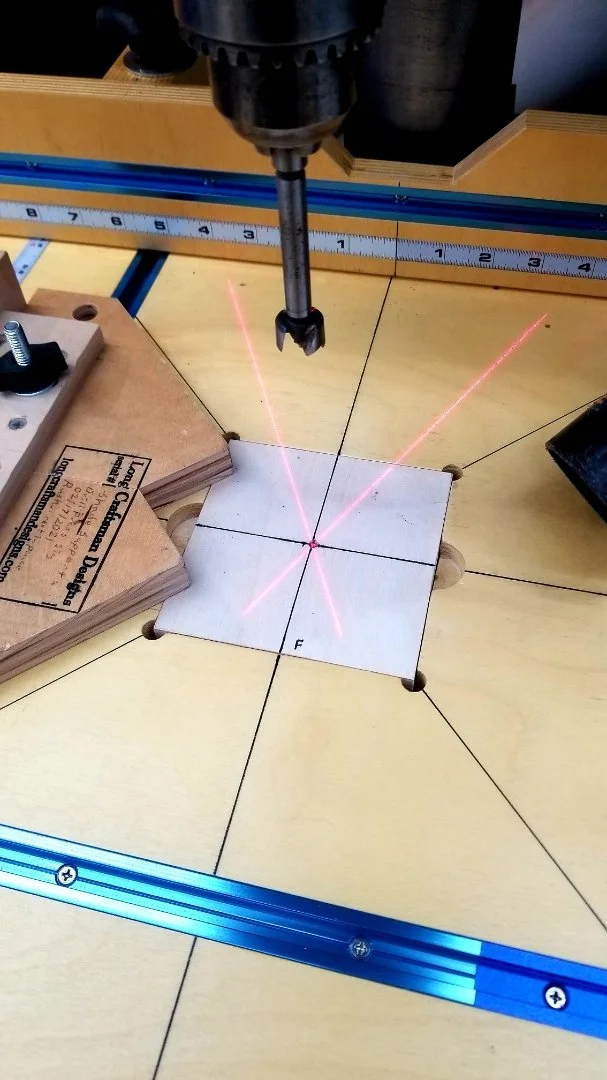

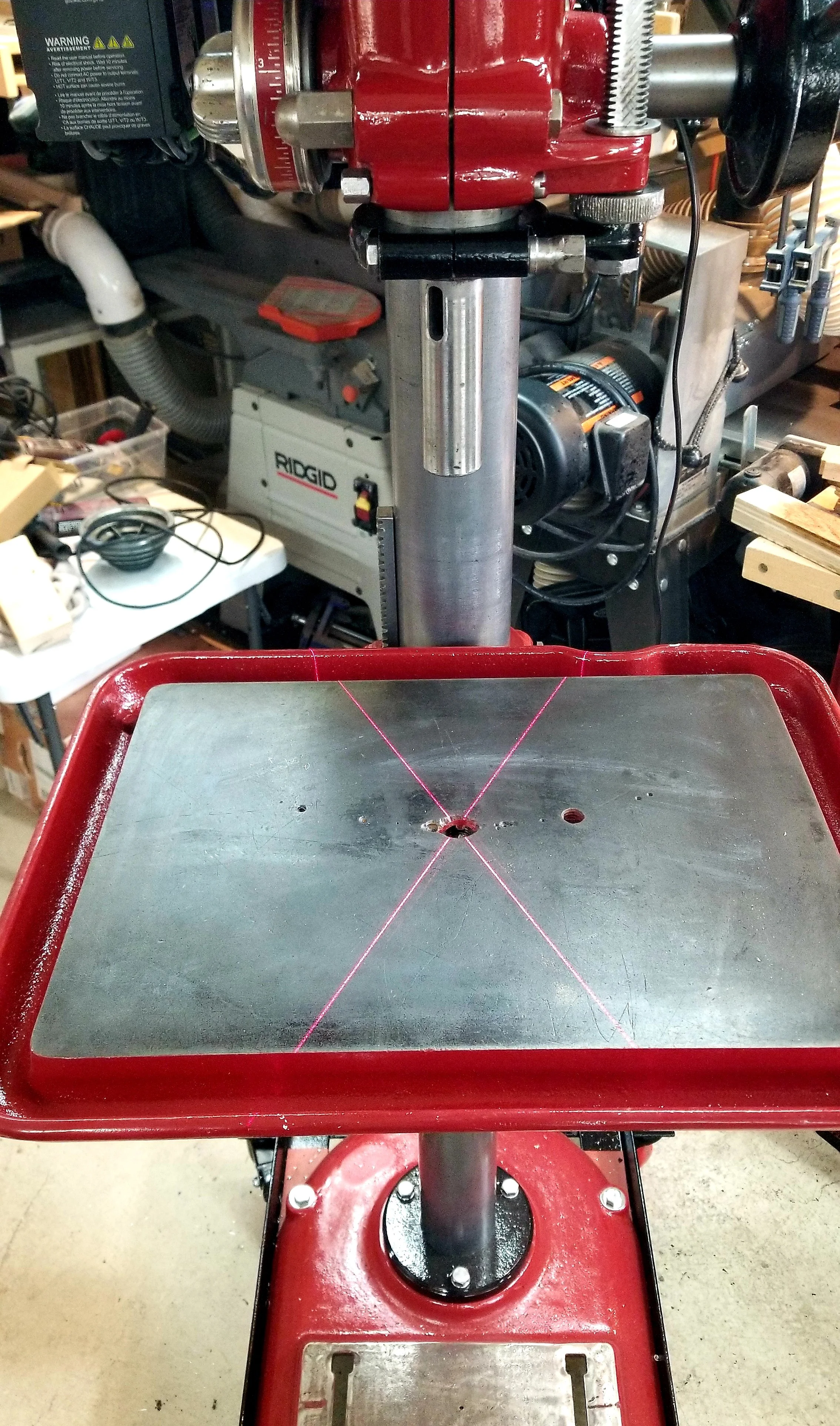

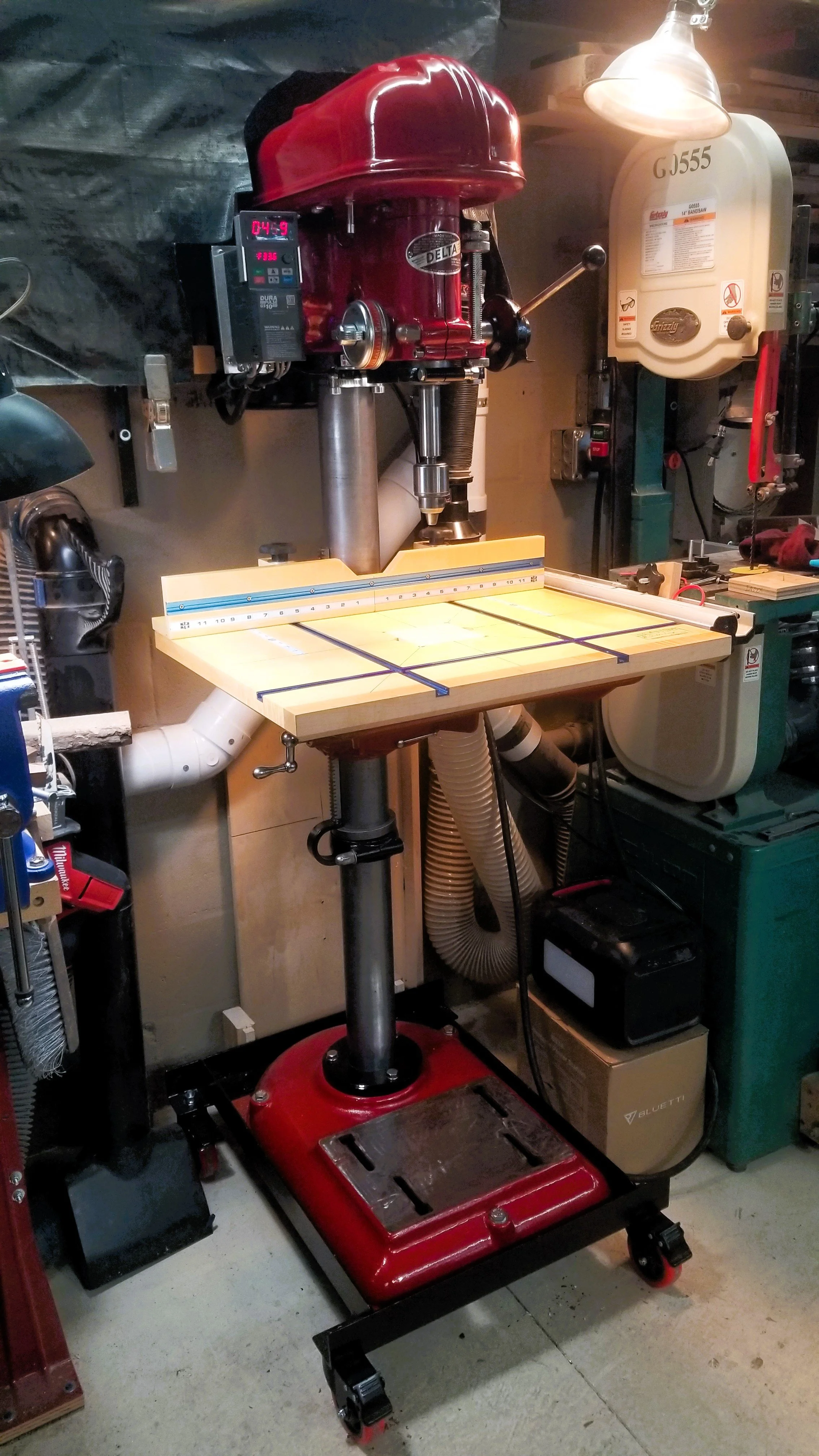

Laser Guide… Old dog, new tricks. I had gotten used to the laser guide on my Porter Cable DP and went looking for a “universal” one to go on this Delta. Sure enough, there’s one being made by Wixey (Wixey Model WL133 Drill Press Laser) and I found it on Amazon. I have several Wixey measuring tools in my shop and found them to be reliable. One of the reviewers recommended replacing the 2 AAA batteries on the unit with a 3V AC-DC adapter. Brilliant! Since I needed a 120v power strip to power a work light anyway I just plugged the adapter into that and it turns on and off with the switch, now the setup is perfect. The laser lines are bright enough to see, even when my work light is on, and everything powers up and down with the machine.

Tachometer… With the VFD I wanted to know the actual RPM of the spindle. I ordered an inexpensive digital tach from Amazon that uses a Hall effect sensor, basically a magnetic pick up that reads a small magnet as it passes by. I drilled a hole in the bottom of the belt cover aligned with the edge of the front pulley to mount the threaded senor. Then I drilled a small indention in the bottom of the aluminum pulley along it’s edge and glued the little magnet in. I adjusted the sensor so it came close to the spinning pulley and it read the magnet as it spun by, works perfect. The little digital readout panel is mounted above the motor VFD controller.

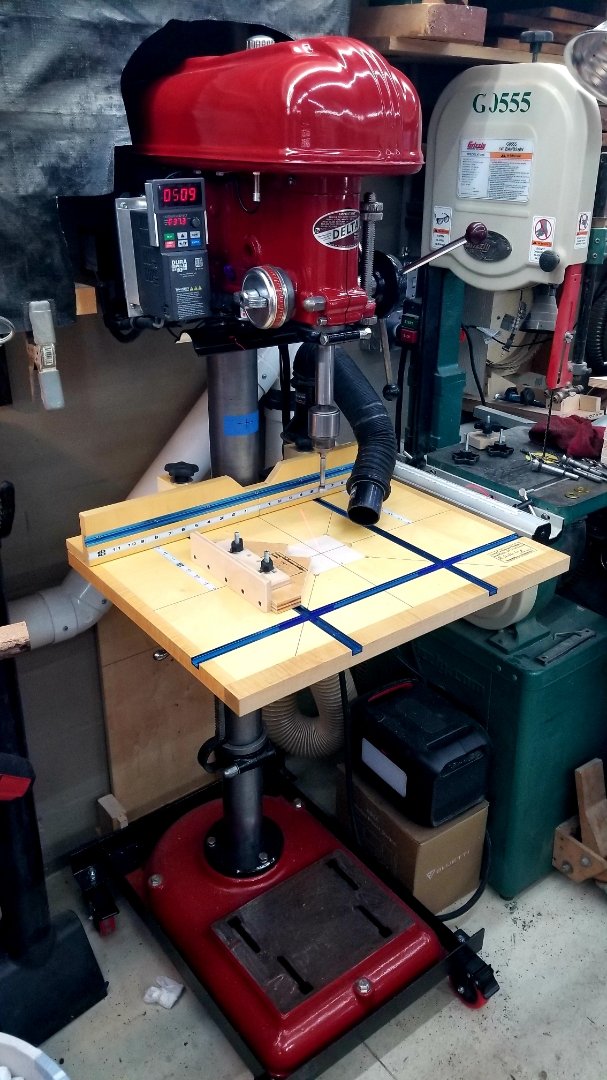

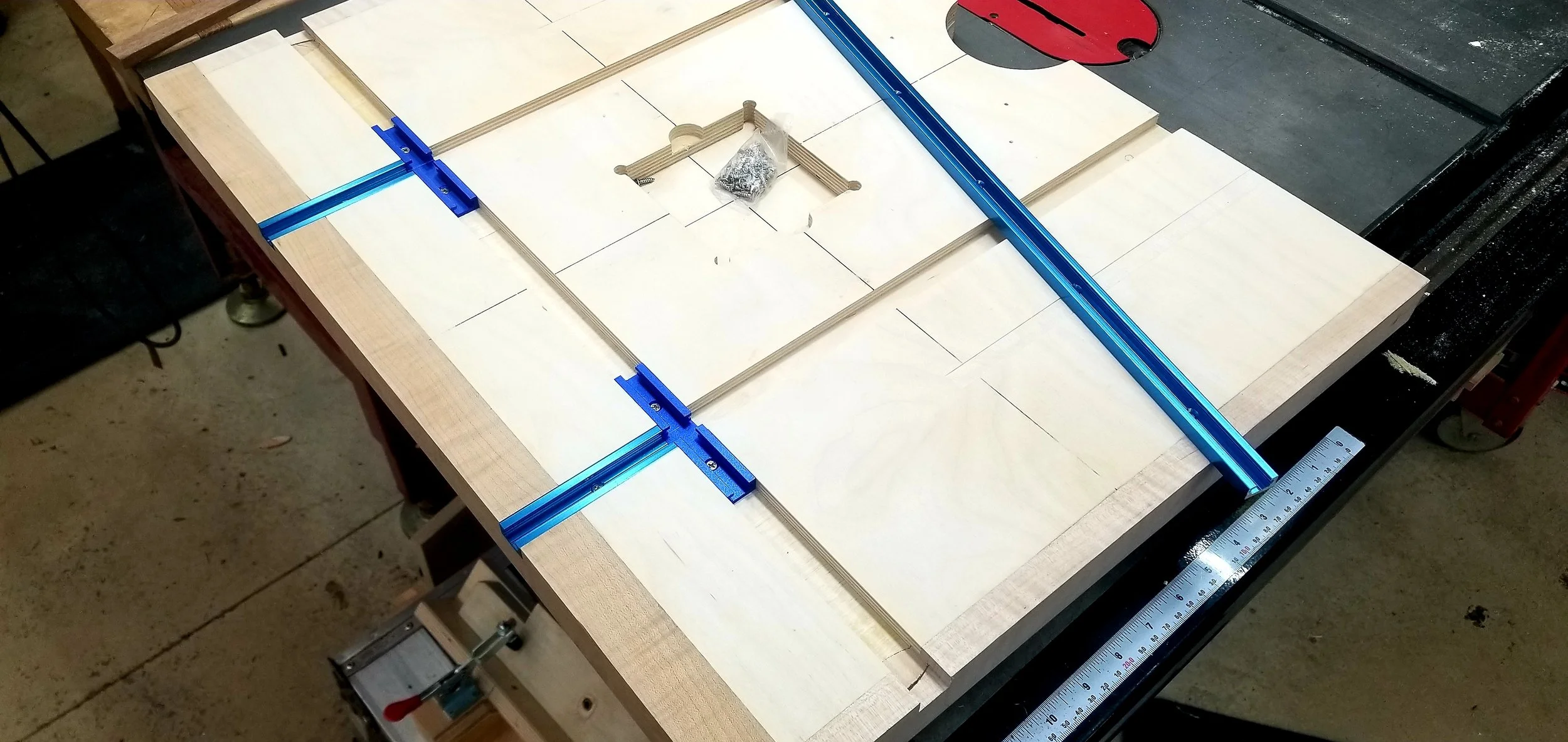

Work table… I had made a nice woodworking table with a fence for my original drill press but after years of use and a bunch of ideas it was time to build another with better features and larger capacity to go with this large press. I started with a double layer of 3/4” Baltic Birch, the bottom layer has threaded inserts that let me use threaded knobs to bolt the thing down to the steel table and the top layer has a cutout in the center for 4”x4” replaceable plugs that the drill bits can cut into without damaging the table. Plenty of stick on measuring tapes that show positions of the fence and T-tracks for the fence to lock down on and for part hold down clamps. I have also made a number over sized fences and jigs that bolt down in the T-tracks to hold specific parts. With the great vertical table adjustment of this Delta press, I can make amazingly deep and straight holes. One of my lamps has a 5/8”x 13.5”deep hole, I often drill this through walnut and quarter sawn oak with no problem. The table is one of the best features of this setup and has allowed me to increase my accuracy and capacity more than I expected.

Overall, this project was a lot of work, but it is by far my favorite machine in the shop and gets used almost daily. I like to think that it’s happy being here, almost like it’s in retirement after all those years of hard work. It got a heart transplant (new quiet motor), a bath and fresh clothes (paint and polish) and new electronics for some bling, plus it lives a life of leisure with light work in a climate controlled environment. Got to love it!!!